SOLDER-PASTE WETTING TESTER

(SP-2)

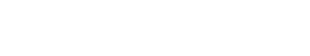

SP-2 is wettability testing machine for solder paste, parts electrode and PC board, adopted SP-Tension-Method (Temperature Profile Method)

Three measurement methods

Observation the process of wetting

Feature

- ●Can test and evaluate solder paste, PC board and parts-lead.

- ●All wetting process can be observed from glass windows.

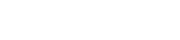

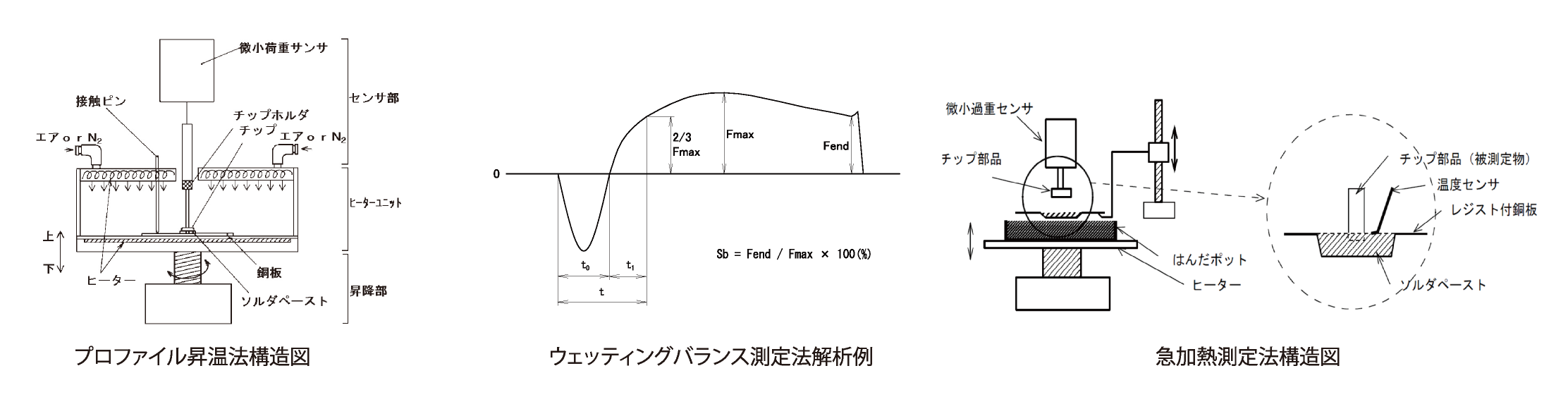

- ●"Wetting Balance Measuring Method","Micro-Wetting Balance Measuring Method", and "Quick Heating Method"

are possible optionally. - ●Can simulate reflow oven profile with hot air and N2 purge.

- ●Electro-balance sensor adopted allows detection of very small force.The wettability of microchips can now be

examined by this unit. - ●Analyze wetting time and force with exclusive software.

- ●Solder wire testing is also available.

product specification

| Item | Specifications | |

| Load Sensor | Principle | Electro - balance sensor |

| Measurement range | 10.00gf~-5.00gf | |

| Measurement accuracy * | ± (10mgf + 1 digit) | |

| Resolution | Less than 900 mgf: 0.001 gf More than 900 mgf: 0.005 gf | |

| Temp. Sensor | Measurement range | 0~300℃ |

| Measurement accuracy | ±3℃ | |

| Heater unit | Temp. of heater unit | Room temperature ~ 300℃ |

| O2 Concentration | Simple closed heater unit with nipple for N2 purge test | |

| Temp. profile setting |

1. Preheat temp. 2. Preheat time 3. The rate of temp. rise 3℃ /sec. (standard) 4. Maximum temp. 5. Maximum temp. time |

|

| Melting point | Preset solder paste melting point | |

| Table movement |

Automatic: operated by PC Manual: operated by Up/Down switch (selectable 3 steps speed) |

|

| Digital output | RS-232C cable (Malcom format) | |

| Air supply |

Original air pressure: 0.2~0.5 Mpa (Approx. 2~5 kgf / cm2) Adjustment air: 0.2 Mpa (Approx. 2kgf / cm2 ) |

|

| Power supply | AC100V 50 / 60Hz 700W | |

| Weight | Approx. 20kg | |

- *Load sensor accuracy is not concerned oscillation.