TABLE TOP MODULE REFLOW OVEN(RDT-250C)

High heating performance in spite of its small size allows for prototyping, heating test, evaluation and production.

It is a best-selling machine.

High Δt performance

Table Top Type

Feature

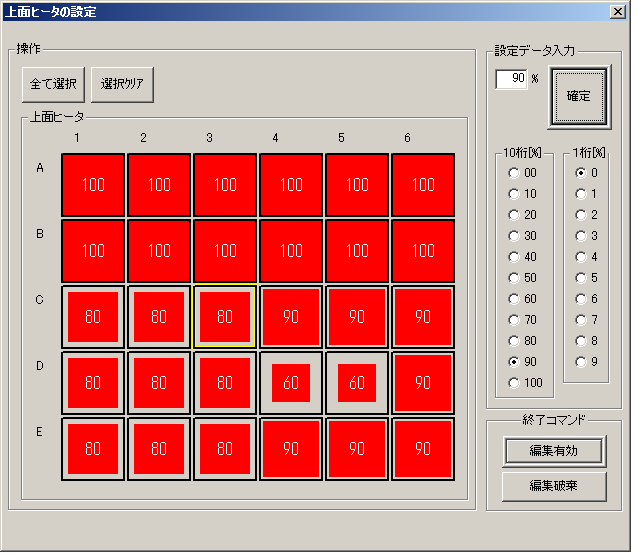

- ●The local matrix control system of upper heater makes possible for reflow soldering less than 5C.

- ●The ideal trapezoid profile heating for lead-free soldering can be made easily.

- ●Low power consumption provides excellent cost-performance benefits.

product specification

| Item | Specification |

| Model Name | RDT-250C |

| Applicable Circuit Board | Up to 250W x 330L x 15H mm |

| Outer Dimension | 830(W)×557(D)×523(H)(mm) |

| Heating Method | Upper-face : Extreme infrared radiation with hot air

Lower-face : Extreme infrared radiation |

| Cooling Method | Exhaust damper continuous operation by flowing air or N2 air

(with flow adjustable valve) |

| Power Supply | 200V 50/60Hz 18kVA 3Phase |

| Air | 0.3 - 0.5MPa 100 liter/min (Maximum) |

| O2 Concentration in Furnace

(when using N2) |

100ppm minimum |

| PCB Installation | Net system or Carrier system (Selectable on request) |

| Upper-Heater | Extreme infrared radiation with hot air heater : 7.2kW (Approx.240W x 30 block) * Adjustments can be made using the Matrix control system Hot air heater : 8kW (2kW x 4) |

| Lower-Heater | Extreme infrared radiation heater : Approx. 2kW (330W x 6) |

| Temp. Accuracy | Room temp. - 80C : +/-3C 80C - 330C : +/-2C |

| Measuring Temp. Range | Room temp. - 330C |

| Measuring Points | 1 - 6 points |

| N2 Gas Supply Function | 100 liter/min. with flow regulating valve during operation. |

| Control | Exclusive softwarefor Windows XP/2000 |

| Weight | Approx. 110kg |

- Option : OXYGEN ANALYZER

- Option : N2 FLOW MIXING METER

- * The above specifications are subject to change without notice.